Campus workspace helps students bring their ideas to life

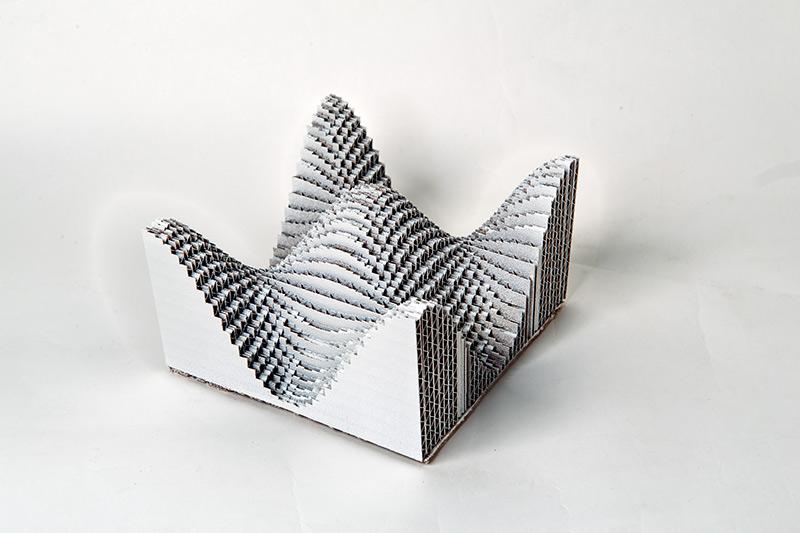

If a student can dream it, they can create it thanks to the Tulane University MakerSpace, a student-run workshop that offers accessibility to laser cutters, 3-D printers and other design tools. The workshop caters to the university’s artists, engineers, craftspersons, makers and kinesthetic learners on the uptown campus.

The equipment is available for academic assignments as well as for extracurricular projects that require mechanical manufacturing to all Tulane students as well as faculty and staff.

Cedric Walker, professor emeritus, spearheaded the establishment of MakerSpace at Tulane alongside colleagues Tim Schuler, senior professor of practice in physics and engineering physics, and John Sullivan, a lab supervisor in biomedical engineering.

Walker said that Tulane’s MakerSpace is unique in that it has a partnership with the Newcomb Art Department, bringing together students of science and engineering with art students.

In full operation since 2016, the 4,100-square-foot workshop is used regularly by students and faculty across many disciplines.

“An anthropologist wanted to show his students an excavated deer mandible that had human teeth marks on it from 8,000 years ago,” said Walker. “It was too fragile to pass around, but the professor was able to use a CAT scan of the bone to create a 3-D model for the students to view up close.”

Similarly, Walker recalled a linguistics student who came in to replicate a flute made of bone that was too fragile to play. The student, who was studying the sounds of ancient instruments, “was able to give voice to a flute that had not been heard in 3,000 years.”

Another selling point of Tulane’s MakerSpace is the fact that daily operations are entirely student run. Walker, who retired from his 39-year career as a professor of biomedical engineering at Tulane in 2015, works part-time to help students with training and ordering supplies.

“When you come in to the workshop there is no staff and no faculty. Students are in charge,” said Walker. “They are here to help users, but they also have the authority to throw someone out if they are doing something that isn’t safe.”

To encourage creativity among students, the Maker of the Year award was established in 2016 to recognize those who have mastered the complexities of building using the items available in the workshop. Afsheen Sajjadi, the inaugural Maker of the Year, is a biomedical engineering student who took the prize for designing a weight-bearing bridge using a laser cutter. He is also one of the workshop’s student workers, who are affectionately known as Maker Ninjas.

“I enjoy helping people who come in with an idea make it into something real,” said Sajjadi. “Most people come in with a plan and they leave with this thing they’ve made that they are proud of.”

Like this article? Keep reading: Inventions take shape with Tulane assistance